How to prevent hot work die from early failure

- The way of the early failure for the application in casting die.

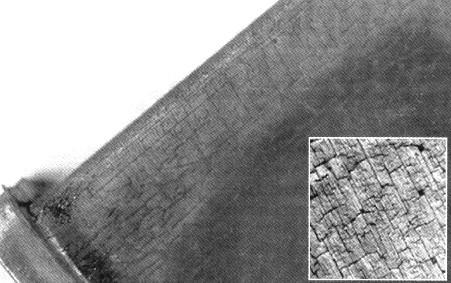

- 1、Thermal cracking

- 2、crack

- 3、corrade

- 4、Corrosion / adhesion

- 5、Sag

- Thermal cracking

- It caused by the comprehensive effect of alternating thermal stress, tensile stress and plastic strain .

- Early thermal cracking reason

- 1、material

- 2、design

- 3、mould produce

- 4、heat and surface treatment

- 5、production period

- 6、the welding surface

- 7、A highly polished surface

- 9、The none oxidized surface

- 10、cutting Machining is not enough

- Early thermal cracking reason – heat and surface treatment

- 1、low hardness

- 2、quenching organization is not ok

- 3、Decarburization

- 4、The nitride layer is too thick,

- Early thermal cracking reason– production

- 1、the temperature for the mould is not enough high

- 2、Gas flame to heat

- 3、(High cycle times)

- 4、he metal liquid temperature is too high

- 5、injection speed is too fast

- 6、Release agent spray too much .

- 7、coolant temperature is too low

- 8、The overall cracking damage

- adhesion

Due to the forminga for a serious of intermetallic compounds , it made the die cast metal adhered on the surface

- 1、The reason of corrosion and adhesion

- 2、temperature of the die cast metal

- 3、The chemistry element for the die cast metal

- 4、injection speed for the die cast metal

- 5、surface treatment for the mould

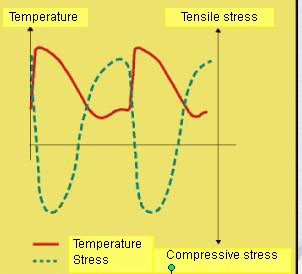

- the mould surface temperature and stress distribution curve

The cooling cycle time of the die surface is important for the thermal cracking

- Early thermal cracking reason–design

- 1、Cooling water is too close to the die surface

- 2、existing of high stress zone

- Early thermal cracking reason– mould production

- 1、surface EDM layer

- The mould is thermal overload and and mechanical overload in short time

- The reason for the overall cracking

- 1、material

- 2、heat treatment

- 3、mould production

- 4、die casting operation

- 5、mould maintenance and care

- Erosion reasons

- 1、hot hardness for the mould material

- 2、The lubrication of mould

- 3、Injection speed for the casting metal

- 4、The temperature for die cast metal

- 5、The chemical composition of casting metal

- 6、Surface treatment of mold

- corrode

- When the surface without protection, the die cast metal will be diffusion and spread into the surface of the mould .At the same time, the mold metal will be spread into the die cast metal also.The diffusion will form intermetallic compound between the casting die and surface of the mould .