- he product table for Nippon stainless iron of steel production.

|

steel name |

elemen |

characteristic |

|

420J2 |

(C)0.30%、(Cr)13.2%、S Content is less than the United States ASTM standards |

Can use oil quenching, HRC53-56, characteristic :pass through ESR, sharp, good toughness, wear resistance ability is good, not easy to rust. |

|

420HC |

0.42%, (Cr) 13.5%, MO, V appropriate amount. The S content is less than the United States ASTM standards |

Heat treatment can be up to 56-58HRC. Characteristics :pass through ESR, uniform quality, sharp, anti rust, high toughness, high wear resistance, not easy to break off the crisp, finer grains, Suitable for high impact tools, cutting tools. |

|

440A series of special tool steel |

(C)0.75%, (Cr) 17%, Mo, V appropriate amount. The S content is less than the United States ASTM standards |

After heat treatment, the hardness of 58-60HRC. Characteristics:pass through ESR, uniform quality, sharp, anti rust, high toughness, high wear resistance, not easy to break off the crisp, finer grains. Suitable for high impact tools, cutting tools. |

|

425M series of special tool steel (S7+ CR) |

(C)0.50%, (Cr) 14.5%, Mo, V appropriate amount, the content of S is less than the United States ASTM standards |

- 420HC heat treatment work technic:

- HRC53-We suggest using 1030-1080 ℃ vacuum furnace to quenching .the gas quenching or oil quenching, we suggested using gas quenching, tempering at 170-260 ℃, the hardness degree will be up to HRC58 . we recommended the tool hardness to use HRC53-54 degrees (tempering temperature at 180-220 ℃) it will be strength toughness, wear resistance, excellent intensity .

- The cutting tool hardness: HRC54-56 degrees (tempering temperature 170-210 ℃), It will be strength toughness, wear resistance, excellent intensity.

- The high temperature tempering (more than 500 DEG C),it will be greatly reduced the hardness , but the toughness will be better than before.

- heat treatment work technic:

- For the above grade,to use 1050 ℃± 10 ℃ quenching temperature ,the overall performance of the hardness and toughness will be better , For 1080 ℃ quenching temperature ,the hardness is higher, Suggesting the heat treatment time to be keep around 0.8-2 hours, and when it is heating process ,it should take protective measures to prevent oxidation, The quenching must be best use of protective atmosphere or vacuum furnace to heating, If the furnace wall is thin, the wall insulation time will be shorter, whereas it will be longer.

- Tempering at 250 ℃ and low austenite temperature quenching,it will get good comprehensive performance, especially the toughness, but the hardness is common.

- The basic formula of heat preservation time——Thickness mmmm×(1-1.5H)分/mm。

- The cooling method is recommended to use rapid air cooling.

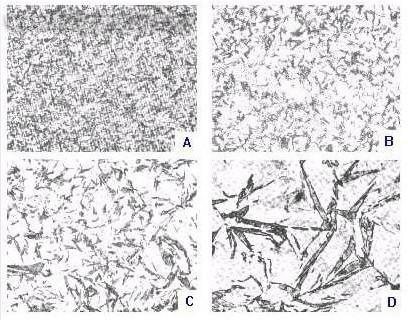

- The quenching temperature is higher, the martensite piston driver will be more coarse.

- For the photo D ,the Martensite organization is the most crassitude, its strength and ductility is the worst.

- Quenching temperature is at 1030 ℃ the toughness is the best , at 1080 ℃ the toughness is the worst.